is no longer your problem

Discover our unique solutions to recycle homogeneous catalysts

because they are so precious, to your business and to the environment.

Homogeneous precious metal catalysts are hard to recover from liquid waste.

Inda-MP is Indaver’s state-of-the-art facility, dedicated for recovering precious metals from liquids typically originating from reactions based on homogeneous catalysts. Inda-MP offers an efficient, one-stop solution, from logistics of the liquid phases until delivery of the refined precious metals. So you can focus on your production process.

Discover how we bring precious metals back to life

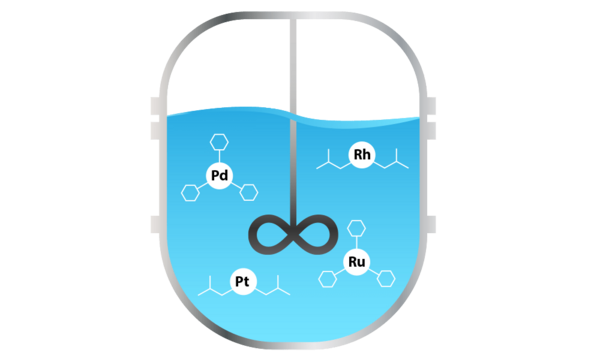

Inda-MP recycles precious metals from liquids. A large part of these liquids originate from reactions based on homogeneous precious metal catalysts, used in pharmaceutical and chemical industry or from the manufacturing of fuel cells. After the production process the precious metals remain diluted in the liquid waste which can be aqueous or solvent based. These liquids can be characterized by hazardous, toxic, flammable and corrosive properties.

These liquids containing precious metals are collected and transported to the Inda-MP facility. The facility consists of 2 process lines, and it offers a wide range of techniques, including precipitation, adsorption, thermal methods and others.

During the recycling process the precious metals are recovered with very high efficiency while hazardous components are safely destroyed. Valuable solvents can be further purified and reused. Inda-MP offers economic solutions starting from a few ppm of precious metals.

Homogeneous catalysts

Homogeneous precious metals catalysts are organometallic complexes which are dissolved in the reaction mixture. These catalysts are increasingly used thanks to their specific features, like selectivity and activity, which enable new chemistries.

After the reaction the catalysts end up in the waste liquid phases where they may degrade or decompose. These liquids typically have complex compositions and may be flammable, toxic or corrosive.

Offering highly efficient treatment solutions for those liquid phases is Inda-MP’s added value.

Benefits of recycling precious metals?

Economics

Avoiding purchases of primary precious metals

Environment

Recovery of your precious metals reduces your environmental impact and carbon footprint significantly

Security of supply

Avoid raw material supply risks through the reuse of your precious metals

Why Inda-MP?

Always a solution

Multiple technologies and installations enable a solution for every liquid stream.

One-stop solution

Inda-MP manages the complete supply chain, from logistics of the liquids until final delivery of the refined precious metals.

Transparency

The full amount of recovered precious metal is registered and communicated in all openness.

Our customers

Pfizer’s Ringaskiddy complex in Co. Cork, Ireland is the largest Pfizer production facility outside the US.

Palladium catalysts are used to speed up chemical reactions in our R&D processes. Unfortunately, these type of catalysts are completely dissolved in the liquid reaction phase. Pfizer could not separate/recover with its own internal techniques. This resulted in loss of valuable and expensive material which needs to be purchased each time. As our total waste management partner Indaver came up with a solution after we jointly investigated the chemistry at molecular level. The precious metal recovery project was set up and delivered large environmental & financial benefits to Pfizer.

Innovative separation techniques lead to excellent recovery results

Brian O'Rourke, Cost Reduction Specialist for Waste at Pfizer

Inda-MP is part of the Indaver Group, a European waste management company

and partner in the circular economy